URL: https://belle2.desy.de/e101530/e101536/@@siteview

Breadcrumb Navigation

Vertex Detector Cooling

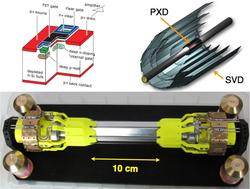

Figure 1: DEPFET (Depleted p-channel FET) principle (upper left). Schematics of the Belle II vertex detector (PXD) being surrounded by the strip detector (SVD). Mechanical PXD mock-up (below)

In summer 2011 DESY joined a consortium of several German institutes (Bonn, Heidelberg, Göttingen, Gießen, Karlsruhe, TU Munich, LMU Munich and MPI Munich) that is responsible for designing, building, installing and operating the pixel detector as part of the Belle II experiment. The design of the new pixel detector is based on the DEPFET technology (figure 1 upper left) that was originally developed for the ILC and allows to build very thin sensors which is important to minimize the effect of multiple scattering of the relatively low energy decay particles produced in the collisions.

The DESY group is in charge of building a thermal mock-up in order to study and optimize the complex cooling system for the entire vertex detector (figure 1 upper right). The test system consists of models of the central beam pipe, the two layer pixel detector and four layers of silicon strip detectors, the latter being built by the HEPHY institute in Vienna and by KEK. This activity also includes building and operating a complex evaporative two-phase CO2 cooling plant.